Functions of a Clarifier The final clarifier must perform two pri-mary functionsclarification and thickening. SS removed lbday 63801 lbday.

Circular Primary Clarifier Explained Savree

FLOW 8125 galdayft 650000 galday 80 ft Clarifier Loading Hydraulic Loading - Weir Overflow Rate WOR WOR galdft Flow gallonsday Length of Weir ft Practice 1 A primary clarifier is 18 feet wide 45.

. Determine the mass of suspended solids in the reactor over a 7 - day operating period. Primary Clarifier Design Calculation The clarifiers are used in water and wastewater treatment process to remove suspended solids from water under the sole influence of gravity. From a sample of mixed liquor you determine.

The primary clarifier is used to remove. 16 Primary settling tanks can be rectangular square or round. For example when primary sludge is drawn from clarifiers it is sometimes by gravity and sometimes by direct suction using pumps.

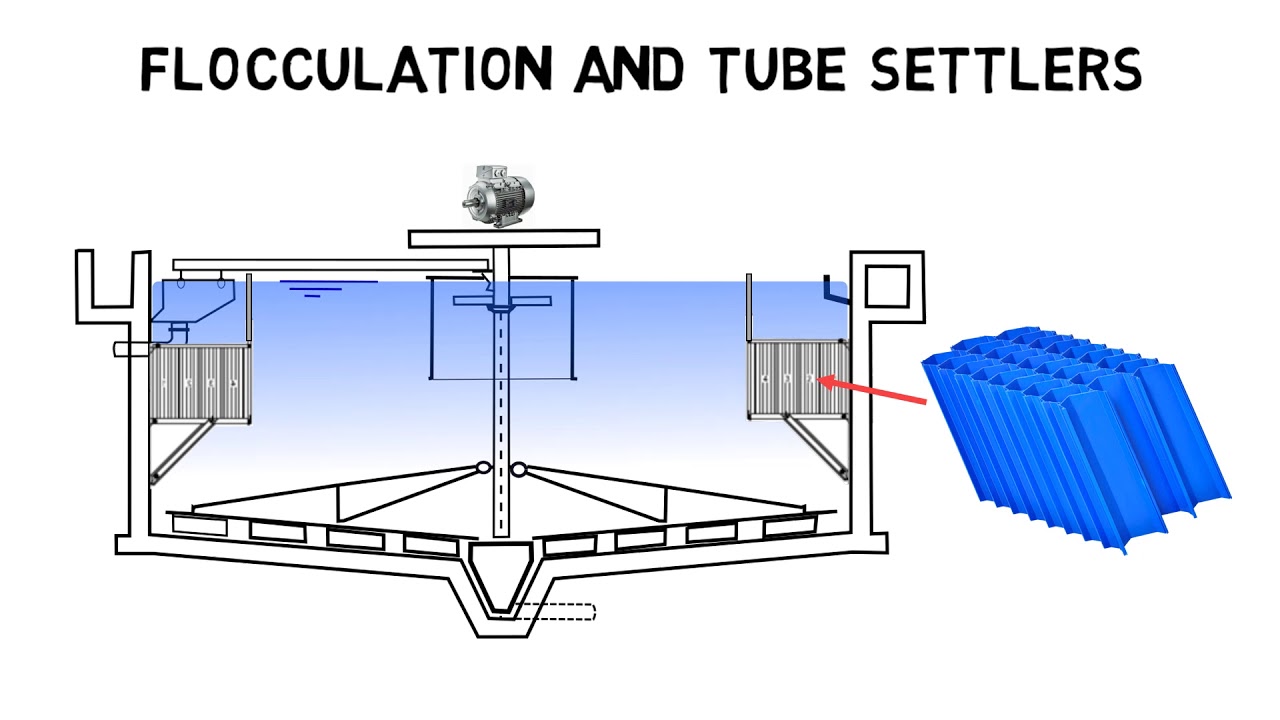

The expected range of surface loadingsettling rate for a primary clarifier is 300 to 1200 gpdsq ft ballpark estimate. This design can be utilized in primary secondary and industrial wastewater applications. The flow to a secondary clarifier is 12 MGD.

37 Full PDFs related to this paper. The expected range of weir overflow rate for a primary clarifier is 10000 to 20000 gpdft. As you can see below a primary settling tank is usually 18 designed with the following parameters.

Impinging exits Submerged floc well Courtesy WesTech Engineering Inc. SS removed lbday 180 mgL x 425 MGD x 834 lbgal. A short summary of this paper.

Learning Objectives At the conclusion of this course the student will. 41 Screening Grit nt Effluent Disinfect Primary Clarifiers Aeration Tanks Secondary. This primary wastewater treatment sedimentation tank will produce a homogeneous liquid capable of being treated biologically and a sludge that can be separately treated or processed.

SS removed lbday SS mgL x Flow MGD x 834 lbgal. Other EDI examples NEWEA Optimizing Clarifier Performance. Monroe Environmentals Primary Circular Clarifiers are designed to receive raw wastewater after it has been pre-screened to remove large objects and grit.

The section below illustrates a typical clarifier design. This course introduces the reader to the key issues and considerations associated with successful and cost-effective design of primary and secondary clarifiers for wastewater treatment plants. If necessary use a settleometer to check how long solids can be in the clarifier without floating to the surface.

Determine also the depth of clear liquid measured from the top of the settled sludge to the. Design a sedimentation unit to provide for. A sequencing batch reactor activated - sludge process is to be used to treat wastewater with the characteristics given below.

Design Example of Settling Channel and Control Device. 4 L 3 Where. 4 6 L 8 L D.

Performance design goals for primary clarifiers are typically quantified based on TSS removal efficiency which normally ranges between 50 and 75 percent and BOD removal efficiency which normally ranges between 25 and 40 percent Tchobanoglous et. Sludge handling in this example consists of removing sludge manually from. DESIGN AND OPERATION ASPECTS November 2017.

Hydraulic Loading Rate Surface Overflow Rate Average Design Flow 800-1200 gpdsq. Clarification is the separation ofsolids from the liquid stream to produce a clarified efflu-ent with low effluent suspended solids ESS. FD-8 Second Edition Prepared by Clarifier Design Task Force of the Water Environment Federation McGraw-Hill New York Chicago San Francisco Lisbon London.

2 THE PROBLEM. From WEF 2005 Clarifier Design Manual of Practice No. Design of primary settling tanks is 2 hours based on the average hourly rate for the 8-.

Surface hydraulic loading rate. HLR Surface hydraulic loading rate mh 3Q primary effluent flow m h A settling tank area m2 Hydraulic retention time. CLARIFIER DESIGN WEF Manual of Practice No.

Of course every wastewater plant is different with potentially vast differences between municipal and industrial wastewater. ACTIVATED SLUDGE PROCESS - EXAMPLE Primary Effluent Return Sludge Mixed Liquor MLSS Aeration Tank. The shape of the tank does 17 not affect its removal efficiencies.

Design Example of SBR. Hydraulic detention time for a primary clarifier is 1 to 3 hours. Designalthough Types IIIand IV settling may also occur to a limited extent.

Primary Clarifiers- How they often impact the process negatively when they are overlooked. PRIMARY CLARIFIER FS-PRI-002 Page 7 of 25 2- DESIGN 21- Design parameters The most important sizing parameters in the primary clarifiers design are. Design calculations for an activated sludge aeration tank and a discussion of activated sludge operational calculations.

Design a set of rectangular grit basins with proportional flow weir for a plant which has a peak flow of 80000 m3day max 3flow of 65000 an average flow of 50000 m day and a minimum flow of 20000 m3day. Activated sludge clarifier design. 3141 Design requirements and criteria.

Calculate the weir over flow rate for this clarifier. Settleable solids 610 mll suspended solids 5580 mgl. The effluent is to have 20 mgL of BOD 5 or less.

To maximize performance the design of primary clarifiers must include features to. Primary clarifiers. The following criteria are recommended for design.

CirCular Clarifier ThiCkener Designs Primary Clarifier Monroe Environmentals primary Circular Clarifiers are designed to receive raw wastewater after it has been prescreened to remove large objects and grit. Removal efficiencies detention times and other parameters have been summarized to provide a handy reference. 52 Design Loading 521 Primary Clarifiers Primary clarifier designs are primarily based upon surface overflow rate.

Example calculations and sample Excel spreadsheets for making the calculations are also included. 20 Detention time of 1 - 2 hrs. Headworks primary BNR AS filtration UV disinfection.

This tool is useful in determining the dimensions of a rectangular clarifier. Guideline and Manual for Planning and Design in Japan JSWA 2009 62 HYDRAULICS OF SLUDGE PIPELINES 621 Sludge Piping Sludge piping can be by gravity or by pumping. Full PDF Package Download Full PDF Package.

Primary and Secondary Clarifiers This page provides information on the expected performance of primary and secondary clarifiers. Usually clarifier design allows for detention times ranging between 2 to 3 hours however it may be as long as 4 to 5 hours. 10 WASTEWATER TREATMENT PLANT.

If 180 mgL suspended solids is removed by the primary clarifier how many lbday suspended solids will be removed when the flow is 4250000 gpd. Make the peak depth equal to the width.

Wastewater Clarifier Performance

Clarifier Basics How Do Clarifiers Work I Clarifier Design Youtube

0 comments

Post a Comment